Delivering Foreign Agricultural Aid to Africa—What Works?

The record of U.S. agricultural development assistance in Africa over the years is uneven. Here’s how involving agribusiness and trade associations can help.

BY BARRY HILL

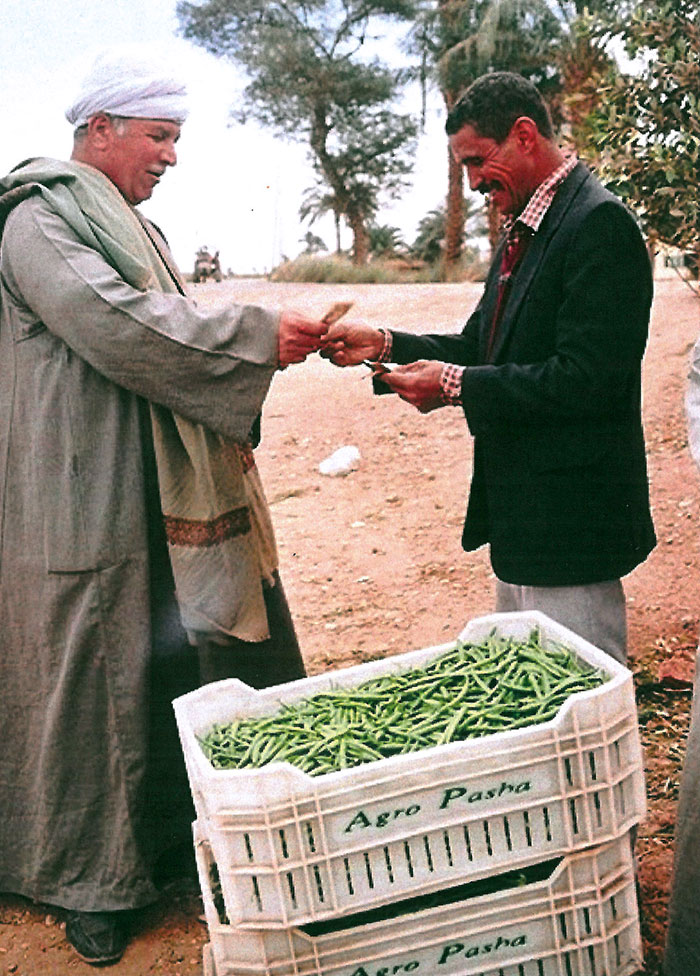

Building solid relationships between farmers and exporters was the key to project success.

Courtesy of Barry Hill

Have we ever considered why project assistance has yet to become institutionalized in many host countries? Are our time frames too short for the aid to take root and generate sustainable progress? Have we ignored key technical resources in the United States that could truly lead to success? Have we missed opportunities to increase farmers’ skills, provide more structure and increase efficiency in their operations? Have we neglected to help build up business relationships among farmers and the supply chains necessary for long-term success?

These questions arise from the uneven record of USAID agricultural interventions over the years. In the following discussion centered on three case studies, I offer some suggestions and guidance for future programming based on my own experience as a USAID Foreign Service officer, observer and evaluator.

A Look at the History

USAID has traditionally used three entities to carry out its agricultural assistance programs: private-sector contractor firms based in Washington (popularly known as the Beltway Bandits), the U.S. Land Grant Colleges that conduct agriculture research, and a covey of nongovernmental organizations (NGOs). Leading this amorphous group were the highly trained, direct-hire USAID agricultural development officers.

Toward the end of the 1980s there was still a skilled and qualified staff of agricultural specialists on USAID’s rosters. As the 1990s opened, however, the administration decided to take foreign aid in a different direction. “Democracy and governance” became the priority emphasis in foreign assistance.

Confusion reigned at USAID as the agency’s leadership struggled to understand what was expected of it under this new paradigm. Technical personnel began departing the agency as their tasks were marginalized and funding for technical activities diminished. Policy wonks came to predominate. Within five years, the agency had been cleared of the majority of its technical staff. USAID’s credibility—especially overseas—took a nose dive, and a lack of quality project tracking and serious technical errors in judgment and planning came to the fore.

Today the powers that be seem to have realized that the typical farmer in Africa is not going to be able to practice any kind of “democracy and governance” if they (1) cannot eat, (2) have poor health that prevents them from working, and (3) don’t have the basic education and practical training needed. As it struggles to field meaningful and workable assistance programs overseas, USAID has initiated new efforts to hire technical staff, yet it faces formidable opposition from Congress over the needed budget.

In this context, a 1991 proposal by the author and a colleague, then in USAID’s Africa Bureau, may hold promise for more effective agricultural development programming. Tasked at that time with devising, presenting and defending an alternative strategy that involved the private sector (agribusiness) in the African overseas development process, we developed the Africa Bureau Agribusiness Strategy. It consisted of different scenarios for development assistance delivery that involved private-sector agribusiness and agribusiness trade associations.

The Case Studies

The brief case studies that follow describe three of the projects using our strategy and their results: (1) informal grant funds utilized in unique ways through U.S. agribusiness associations (Tunisia); (2) forward contracting for production of a single commodity in Eastern Africa, with funding from a European private sector agribusiness (Tanzania); and (3) a USAID-funded large-scale, longer-term effort to create and support privately based farmer associations and engage in forward contracts with European buyers for high-value specialty horticulture products (Egypt).

Case Study 1: U.S. Agribusiness Trade Associations Help Tunisian Producers Increase Output and Marketing

The Setting. I was assigned to Tunisia as an agriculture and resource development officer, arriving in late 1992. A new project had just been approved for immediate implementation, but budget cuts were expected. Our mission director was told by USAID’s Near East Bureau that funding was not only going to be cut, but that the highly sought project would, in fact, be cancelled.

Noting the resulting deterioration in the political climate between the two countries, my mission director and I began to explore possible alternatives. Working closely with the director of the Africa Bureau Technical Group, and with the support of the deputy assistant administrator for the Near East at USAID, we got approval to use $1.5 million of the remaining funds in non-project assistance.

In any project, we need to find the master farmers and involve them directly in developing the technical approach to be adopted for cropping activities.

The Case. Tunisian producers of tomato paste, olives and olive oil, fish and fish products, and milk products were vertically integrated, allowing for smoother melding of production and marketing of the commodities, but in each area there were problems. The Americans were interested in supply chains. Numerous contacts we had made with American agribusiness associations while working on the agribusiness strategy were interested in helping us as we worked closely with Tunisian Ministry of Agriculture field officials.

We made contact with the U.S. National Pizza and Pasta Association (which is no longer in existence), and they sent out a marketing expert who quickly diagnosed that the tomato paste can labels were of such poor quality that no one would buy the product. In response, the American association identified another expert in canning and labeling who was quickly able to suggest easy and cheap solutions to the problem. Similarly, olive oil and canned and bottled olives were not selling well—either locally in the Sahel, or in Europe. We contacted an olive oil processing association in California, and they dispatched a representative expert. She quickly diagnosed the problem, which was very similar to the can label problems of the tomato paste producers, and worked closely with the bottlers and canners to solve it.

Although Tunisian waters produced one of the favorite French-preferred species of fish—popularly called the “loup”—the Tunisian-caught fish were not selling well in Europe. We suspected the root cause was packaging, but we also knew that cold storage issues were a problem. We contacted the International Association of Refrigerated Warehouses, which sent an expert.

He identified three problems: (1) the refrigeration systems the producers used were outdated and not dependable; (2) there was no capability to provide the individually quick-frozen fish popular in Europe; and (3) packaging was of generally poor quality. Another Seattle-based fisheries association sent a representative to work on the packaging and individually quick-frozen issues; while the refrigerated warehouses expert advised new, more efficient and less costly methods to improve the performance of the old refrigeration systems.

That expert also discussed the problems milk producers had maintaining milk freshness. Again, outdated refrigeration systems were at fault, and the consultant suggested the same approach as prescribed for the fishermen. This consultant pointed us to the Food Processing Machinery and Supplies Association, which sent out a representative who was quickly able to help solve the problems, including introducing the production of long-life milk requiring no refrigeration. He also suggested that the Tunisian producers look into cheese production to utilize their excess milk product.

Note that for all the above activities we arranged practical training courses—especially in European import-export protocols and regulations—for the participating producers, as needed.

The Results. The tomato paste producers got new labels on their cans and doubled production and marketing in the next year. The olive oil producers had similar results. The fishermen and processors tripled their export of “loup” to France in the first year, and the milk producers took the association’s advice and installed new, modern refrigeration equipment that solved their major problem with freshness and marketing timing and doubled their deliveries. They also started a new long-life milk production program.

What did all this cost? We had $1.5 million to start. After operating for a year—the time limit on our budget—we had spent only a third of the funds: about $200,000 for air travel and per diem for the consultants, and about $300,000 for training courses. Notably, many of the trade associations paid the airfare and per diem for their professionals.

Case Study 2: Dry Bean Seed Production in Tanzania under Forward Contracting with Private European Agribusiness

The Setting. Soon after my arrival as agriculture and resource development officer in USAID’s northern Tanzania office in the Arusha region, I learned that a representative of the Royal Dutch Seed Company had recently canvassed the region to assess the potential for growing dry bean seed, and I had the opportunity to observe the development of that project.

Egyptian women sort and pack green beans for export to France.

Courtesy of Barry Hill

The Case. The Royal Dutch Seed Company had been experiencing severe problems with disease vectors at its other sites, in Asia, and was searching for a “diseasefree” site. Earlier visits to the Arusha region had found no bean diseases present, and the company decided to invest its own funds to grow disease-free seed.

A seed agronomist arrived in the region and, working with the support of the Arusha regional director, was quickly able to identify the “master farmers” in the growing areas that interested him. The Dutch expert set up and developed a training syllabus that detailed the parameters and restrictions for growing the seed locally. In addition, the expert hired and began training a local Indian-Tanzanian businessman in processing, selecting and bagging the seed.

The program grew like wildfire. Soon, the local farmer count had grown to more than 50, two Dutch agronomists were onsite in Arusha supervising the activities, and eight master farmers were fully engaged. The Indian-Tanzanian entrepreneur set up a unique operation using a conveyor belt system to pass the seed in front of female pickers.

The Results. More than 60 local farmers and 50 women workers were eventually hired and paid directly by a foreign agribusiness. All these farmers were well-taught in approved agronomic practices that would stand them in good stead for the rest of their lives. Meanwhile, the Dutch company reported that the germination rate for the Arusha-grown seed exceeded 85 percent—an unprecedented figure for the company.

Case Study 3: Egyptian Farmers Forward Contract with European Buyers to Grow and Export Specialty Products

The Setting. This case involved a large USAID four-year, $11 million agriculture project awarded to CARE/Egypt in 2003. The objective was to develop private, service-oriented, independent smallholder farmer associations for the export of high-value crops to Europe under forward contracts, like similar projects undertaken by CARE dating from the early 1990s. The project was undertaken in Upper Egypt where unemployment was high and incomes were low. At the time, the region had 37 percent of the country’s total population but 77 percent of its poorest citizens (UNDP Egypt Human Development Report, 2005). I was team leader for a five-person team fielded in 2007 to perform the final evaluation of this project.

The Case. Prior cropping emphasis and patterns in Upper Egypt had depended almost solely on growing sugarcane. When introduced, this project raised the usage of labor to unprecedented levels. Growing green beans and tomatoes took more than three times as much labor as sugarcane; and cantaloupe, more than two times. The total returns for raising green beans, cantaloupe and tomato were 50 percent higher than returns from sugarcane.

Facilitating payment to individual farmers was a very important factor in this project. The buyer made only one direct payment to a single farmer association, which then dispensed the funds to the individual growers. In addition, through the training and technical assistance provided by CARE staff to the associations, they carefully noted price movements and were increasingly able to use their own information resources to find alternate local markets for products that were not exported.

The Results. This project more than paid for itself. Millions of dollars of high-value crops were grown and exported (i.e., French green beans, cantaloupes, table grapes, pomegranates and bell peppers), increasing the incomes of 12,500 poor farmers. The formation of 103 farmer associations was the culmination of village-level efforts by the farmers themselves. Thousands of new jobs were also created for women and landless farmers.

Over the life of the project, more than 160 million Egyptian Pounds (or $27 million) worth of products were grown—$16 million more than the project cost the United States. Of this, $13 million was exported—over 30 percent more than projected—while, unexpectedly, $14 million was sold on the local market.

One of the truly impressive outcomes was the unanticipated impact of the project on rural women linked to the farmer associations’ members through family relationships. Hundreds of women became directly involved in post-harvest picking, cleaning, boxing/bagging, weighing and storage of products for transport.

A final result of this case that truly astounded the evaluation team was the wide acceptance and support by the government for the project, in helping the farmers develop market linkages for sale of products that significantly raised incomes and increased employment for the landless.

One of the truly impressive outcomes was the unanticipated impact of the project on rural women.

Lessons Learned

These and other projects implemented under the Africa Bureau Agribusiness Strategy yielded many valuable practical lessons that are still very relevant today. Among the most important, are the following:

• Good things and results take lots of time. Case 3 was the third in succession of a 10-year linked effort of project activities. We know that in the United States significant time is required for farmers to accept and use modern farm management practices. Both American and African farmers follow the simple adage: “Don’t tell me. Show me.”

• Many African farmers have problems accessing needed inputs and using them correctly. Donors need to recognize that growing products under forward-contracting arrangements must involve the buyer in providing a minimum list of farm inputs and guidance from a skilled agronomist or horticulturist. After that, just leave the farmers alone to get to work.

• African farmers can readily adapt sophisticated agronomic and horticultural practices (if they are convinced they work) to local constraints and conditions. All the donors and experts have to do is listen and learn and adopt and demonstrate.

• Women represent the majority contributors to the agriculture production and marketing process. No project large or small should ever be undertaken without the full participation of women.

• For larger efforts (such as the Egypt project), helping the farmers create community-based farmer organizations should be a top priority. These associations must be created by the farmers themselves (with assistance from donors, as invited).

• In any project, we need to find the master farmers and involve them directly in developing the technical approach for adoption in cropping activities.

• USAID, and other aid agencies as well, should investigate the use of non-project assistance where warranted.

Our strategy was based on the assumption that American agribusinesses and agribusiness trade associations offer powerful tools and capability to assist rural poor farmers overseas. Subsequent project implementation, as presented here, not only proves that to be true but offers insight on how to make best use of those tools and capabilities.

We learned, for instance, that it is optimal to involve agribusiness and trade associations as early as possible in the project, preferably in the design phase. We also learned that donor funding for the creation of local farmer associations is tremendously beneficial; such associations empower the farmers to efficiently organize production and marketing of the product. And, finally, we found that keeping a project running long enough to give it a chance to succeed—10 years at a minimum, if not longer—is essential.

Read More...

- Foreignassistance.gov

- Agriculture and Food Security (USAID)

- The Global Food Security Act is pushing to the finish line, by Eric Muñoz (The Politics of Poverty blog, Oxfam America, April 15, 2016)

- Ten Questions with Pamela Fessenden of the USAID Bureau for Food Security (Food Tank, April 19, 2016)

- $4.8 Million USAID Grant to Strengthen Biotechnology Partnership and Improve Food Security in South Asia (Market Wired, March 29, 2016)